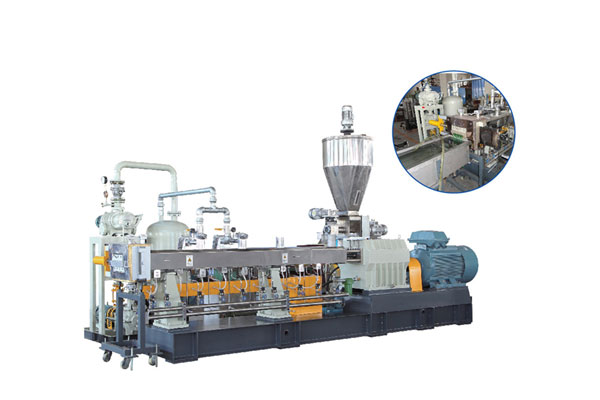

What are the differences between parallel and conical twin-screw extruders?

2019-03-27

According to the direction of rotation of the twin-screw, the extruder can be divided into two extruders: the same direction and the opposite direction. The same direction extruder has the same rotation direction when the two screws work, and the counter-rotating machine refers to two screws. The direction of rotation is opposite when working. According to whether the axis of the twin-screw shaft is parallel or not, it can be divided into two kinds of extruders whose axis line is parallel and the axis line intersects. The axis line is parallel to the twin-screw extruder, and the axis line intersects as a cone. Shape twin screw extruder. Twin-screw extruders also have meshing and non-engaging parts. Parallel and conical twin-screw extruders have the same advantages: there is a transfer mechanism for forced advancement of plastics, good mixing and plasticizing ability and dewatering capacity, and have the same adaptability to the molding process of materials and plastic products. Parallel to the difference between a conical twin-screw extruder 1. Diameter: The diameter of the parallel twin screw is the same. The diameter of the small end of the tapered twin screw is different from the diameter of the big end. 2, concentric distance: the center distance of the flat twin screw is the same, the two axes of the conical twin screw are at an angle, and the size of the center distance varies along the axis. 3. Length to diameter ratio: Parallel double screw (L/D) refers to the ratio of the effective part length of the screw to the outer circle of the screw. The conical twin screw (L/D) refers to the effective part length and the large end diameter and small of the screw. The ratio of the average of the end diameters.