Plastic Granulating Machine

Force Feeding Single Screw Extruder Granulator

Force Feeding Single Screw Extruder Granulator

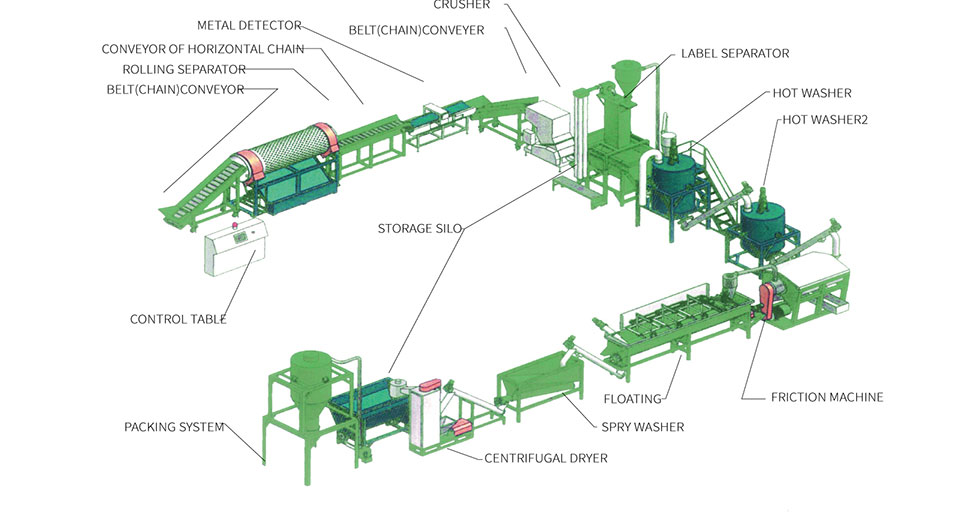

Force Feeding Single Screw Extruder Granulator  Force feeding type has also come to be known as economical pelletizing as economical pelletizing type as it recycle a variety of raw materials.

Force feeding type has also come to be known as economical pelletizing as economical pelletizing type as it recycle a variety of raw materials.  The main extruder provides the best feeding ,mixing , ventilation , heating and capacity as it is designed way based on customer’s raw material,capacity ,and compounding degree.

The main extruder provides the best feeding ,mixing , ventilation , heating and capacity as it is designed way based on customer’s raw material,capacity ,and compounding degree.  Sub extruder conducts second time filtering and ventilating for dirtier materials.

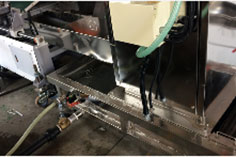

Sub extruder conducts second time filtering and ventilating for dirtier materials.  High speed dryer is soundproof with double layer sealing design.The underneath water tank can gather the waste water and filter the impurity.

High speed dryer is soundproof with double layer sealing design.The underneath water tank can gather the waste water and filter the impurity.  Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryers.

Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryers.  The cyclone gathers the pellets and reduces the impact after high speed dryer prior to next vibrating screener.

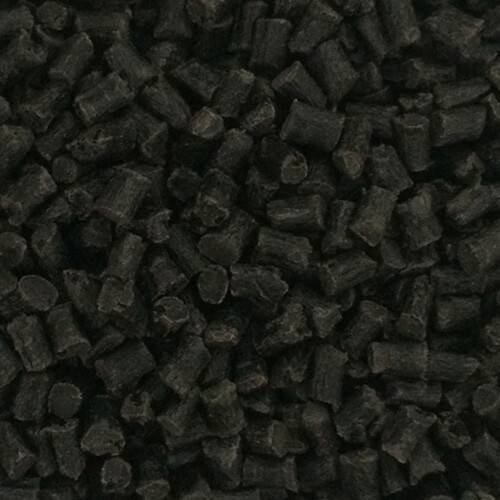

The cyclone gathers the pellets and reduces the impact after high speed dryer prior to next vibrating screener.  The triple layers vibrating screener is easy to clean ,disassemble and assemble .Can customize the diameter of the hole.

The triple layers vibrating screener is easy to clean ,disassemble and assemble .Can customize the diameter of the hole. High torsion, low-noice; temp. controls stability; double degassing

Suitable for a variety of raw materials.

Easy to operate; prority transcends traditional model.

Low labor cost.

Optional equipment- crusher and mixer, enables every batch of material to mix well.

Two stages filter makes material more clean.

Materials

PP Woven Bag

PE Film

ABS

PE Agricultural Films

Specification

| Model | SJ45 | SJ65 | SJ80 | SJ90 | SJ100 | SJ120 | SJ150 | SJ160 | SJ180 | SJ200 |

| Single screw Extruder | ||||||||||

| Screw diameter(mm) | 45 | 65 | 80 | 90 | 100 | 120 | 150 | 160 | 180 | 200 |

| L/D | 18-42 | |||||||||

| Rotary speed(r/min) | 0-150 | |||||||||

| Capacity(kg/h) | 2-40 | 10-60 | 10-150 | 180-250 | 250-400 | 300-500 | 400-800 | 800-1000 | 1000-1500 | 1500-2000 |