Plastic Granulating Machine

PE Double Stage Strand Pelletizing Line

single screw extruder

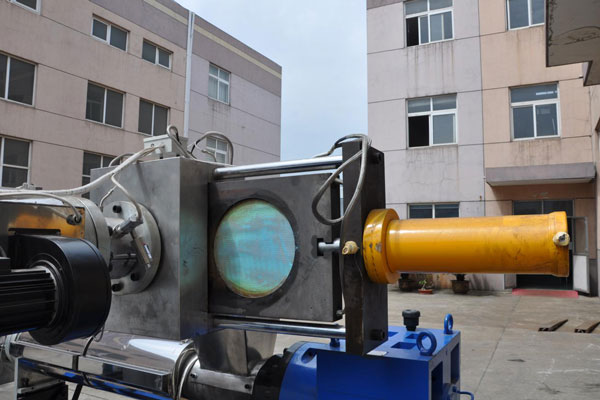

single screw extruder  (Hydraulic screen exchanger)

Double-plate type screen changer realizes non-stopping screen

Hydraulic screen exchange together with the hydraulic station usage,Used for filtration of the material mixture

(Hydraulic screen exchanger)

Double-plate type screen changer realizes non-stopping screen

Hydraulic screen exchange together with the hydraulic station usage,Used for filtration of the material mixture single screw extruder

single screw extruder (Hydraulic station)

Include the Energy Saver to increase the change net speed

(Hydraulic station)

Include the Energy Saver to increase the change net speed Description

plastic granulate machine is the successor to plastic master-sub granulator.

plastic granulate machine is installed by "one line" shape, "right and left" shape and "T" shape, which is saving the work space.

This machine is different from waste plastic machine, such as PP, PE, HDPE. especially resolved the problem of high-density polyethylene granulation broken bars.

plastic granulate machine is matched with plastic crusher and granular cutting machine. While the waste plastic materials through crushing and washing, could be put into extruder without drying. But the die head of machine could be electric screen changer or hydraulic screen changer.

Simple process, advanced technology, automatic temperature control, national energy-saving patented heater, low power consumption, non-pollution, high degree of automation.

Materials

HDPE Milk Bottle

Specification

| Model | CVJ100-120 | CVJ120-135 | CVJ150-160 | CVJ180-200 |

| the first extruder | ||||

| L/D | 25-34 | 25-34 | 25-34 | 25-34 |

| powerofmainmotor | 55-75 | 75-110 | 90-132 | 110-185 |

| powerofheating | 40 | 45 | 55 | 70 |

| rotationalspeed(RPM) | 0-120 | 0-120 | 0-110 | 0-110 |

| the second extruder | ||||

| L/D | 10-15 | 10-15 | 10-15 | 8-15 |

| powerofmainmotor | 22-30 | 30-37 | 30-45 | 45-55 |

| powerofheating | 25 | 30 | 35 | 45 |

| rotationalspeed(RPM) | 0-120 | 0-120 | 0-110 | 0-110 |

| output | 150-200 | 200-250 | 300-350 | 350-450 |

| FeedSystem | 1.5KW | 1.5KW | 1.5KW | |

| Screenexchanger | 250mm | 250mm | 250mm | 300mm |

| Hydraulicstation | 2.2KW | 2.2KW | 2.2KW | 3KW |

| WaterTank | 3000*600mm | 3000*600mm | 5000*600mm | |

| DryingSystem | 2.2KW | 2.2KW | 3kw | |

| PelletizerMachine | 5.5KW | 5.5KW | 7.5kw | |

| Vibratingscreen | 1.5KW | 1.5KW | 3KW | |

| Pipelineblowingdrier | 200-300KG/H | 200-300KG/H | 300-350KG/H | 400-600KG/H |

| Storagehopper | 300KG | 300KG | 500KG | 600KG |