Plastic Recycling & Washing machine

PET bottle washing machine

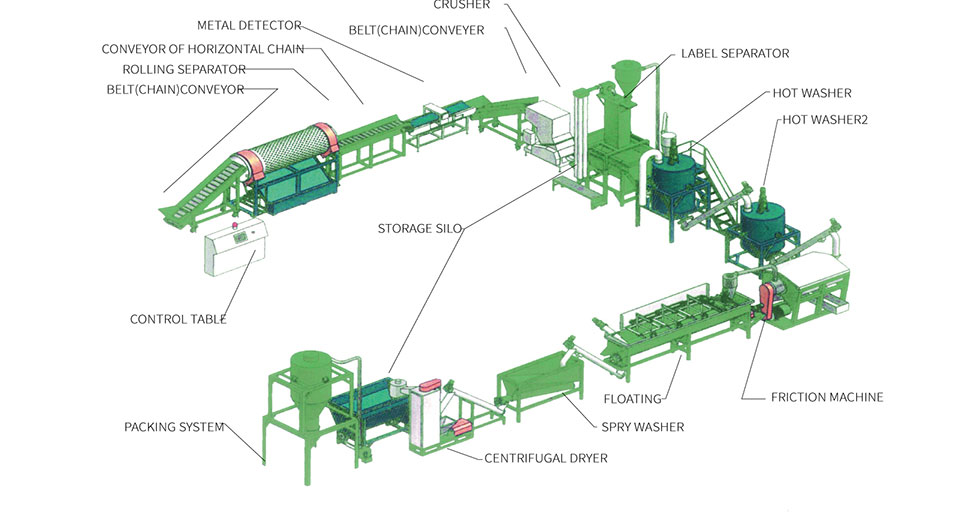

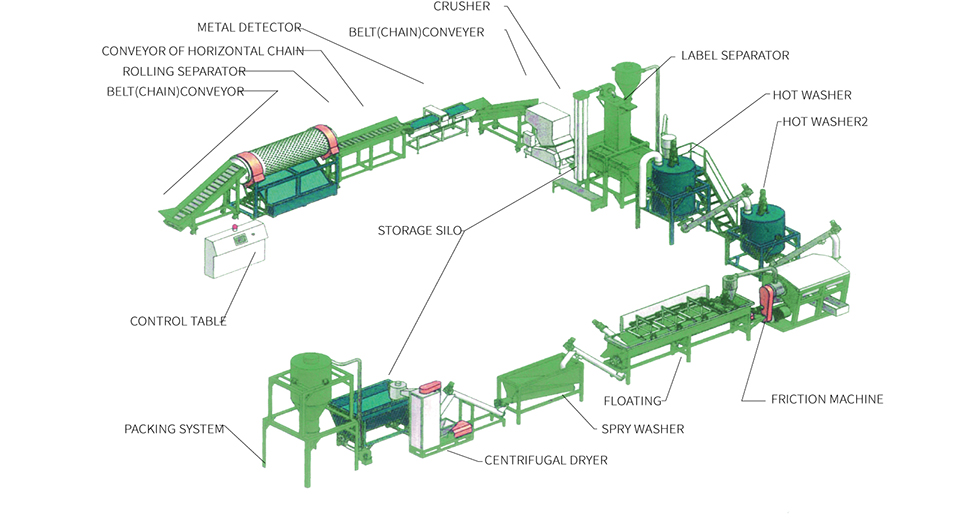

Conveying the bottles into crusher.

Conveying the bottles into crusher.  Automatically separate out sand, rocks, metal, and some bottle caps.

Automatically separate out sand, rocks, metal, and some bottle caps.  Label removing efficiency, more than 98%

Label removing efficiency, more than 98%  Made according to workers' height, supply a suitable plate for selecting the left labels or some other .

Made according to workers' height, supply a suitable plate for selecting the left labels or some other .  Detect ferrous and non-ferrous metals with alarm system.

Detect ferrous and non-ferrous metals with alarm system.  A wet crusher cuts the pp woven bags into small pieces approximately 10-20mm in size and moving onto the next piece of equipment .

A wet crusher cuts the pp woven bags into small pieces approximately 10-20mm in size and moving onto the next piece of equipment .  Conveying the flakes into friction washer.

Conveying the flakes into friction washer.  The dewatering machine uses centrifugal force to spin water moisture off the films and bags .

The dewatering machine uses centrifugal force to spin water moisture off the films and bags .  Using the hot air to take the humidity away from the clean material.

Using the hot air to take the humidity away from the clean material.  A storage hopper for the clean ,dry pieces of pp woven bags .

A storage hopper for the clean ,dry pieces of pp woven bags . Advantages

Final products have good quality. When process PET bottle, final products humidity below 1%, impurities 100ppm, PVC label content 100ppm.

Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service lift time and no second pollution to flakes.

World famous brand components applied on the production line- NSK bearing, Siemens contactor, Omron temperature, FUJI inverter, Siemens PLC control etc.

Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

The whole production equipment is researched, design and manufactured by our company with CE certification, ISO9001 certification; it can be designed based on the dirty flakes, and make sure of the quality of the final products.

Materials

PET bottle

Specification

| Capacity(kg/h) | 200-300 | 450-500 | 900-1000 | 1000-2000 |

| Beltconveyor | ||||

| MotorPower(kw) | 1.5KW | 1.5KW | 2.2KW | 2.2KW |

| Length | 4000mm | 5000mm | 5000mm | 6000mm |

| Rollingseparator | ||||

| Diameterofroller | 1200mm | 1200mm | 1200mm | 1500mm |

| Rollermotorpower | 3KW | 3KW | 3KW | 4KW |

| BottleLabelSeparator | ||||

| MotorPower | 15KW | 22KW | 22KW | 30kw |

| MetalDetector | ||||

| Width | 600mm | 800mm | 800mm | 800mm |

| Crusher | ||||

| MotorPower(kw) | 37kw | 55kw | 55kw | 90kw |

| ScrewLoader | ||||

| MotorPower(kw) | 2.2KW | 2.2KW | 2.2KW | 5.5KW |

| Hotwashingtank | ||||

| MotorPower | 5.5KW | 5.5KW | 5.5KW | 7.5KW |

| ScrewLoader | ||||

| Motorpower | 2.2kw | 2.2KW | 2.2KW | 5.5KW |

| Frictionwashingmachine | ||||

| MotorPower(kw) | 7.5KW | 15kw | 15kw | 45kw |

| ScrewLoader | ||||

| Motorpower | 2.2kw | 2.2KW | 2.2KW | 5.5KW |

| Dewateringmachine | ||||

| MotorPower | 18.5KW | 37KW | 37KW | 55KW |

| Pipelinedryingsystem | ||||

| Heatingpower | 30KW | 60KW | 60KW | 60KW |

| Blowingmotorpower | 5.5KW | 11KW | 11KW | 11KW |

| FlakeLabelseparator | ||||

| MotorPower(kw) | 4kw | 4KW | 4kw | 4kw |