Plastic Granulating Machine

PET Granulating Machine(Parallel Twin Screw Extruder Granulator )

(Blowing System)

Function: to convey the cleaning flakes into the crystallization drying machine

(Blowing System)

Function: to convey the cleaning flakes into the crystallization drying machine  (Crystallization drying machine)

Dry and crystallize the flakes

(Crystallization drying machine)

Dry and crystallize the flakes  Parallel Twin Screw Extruder

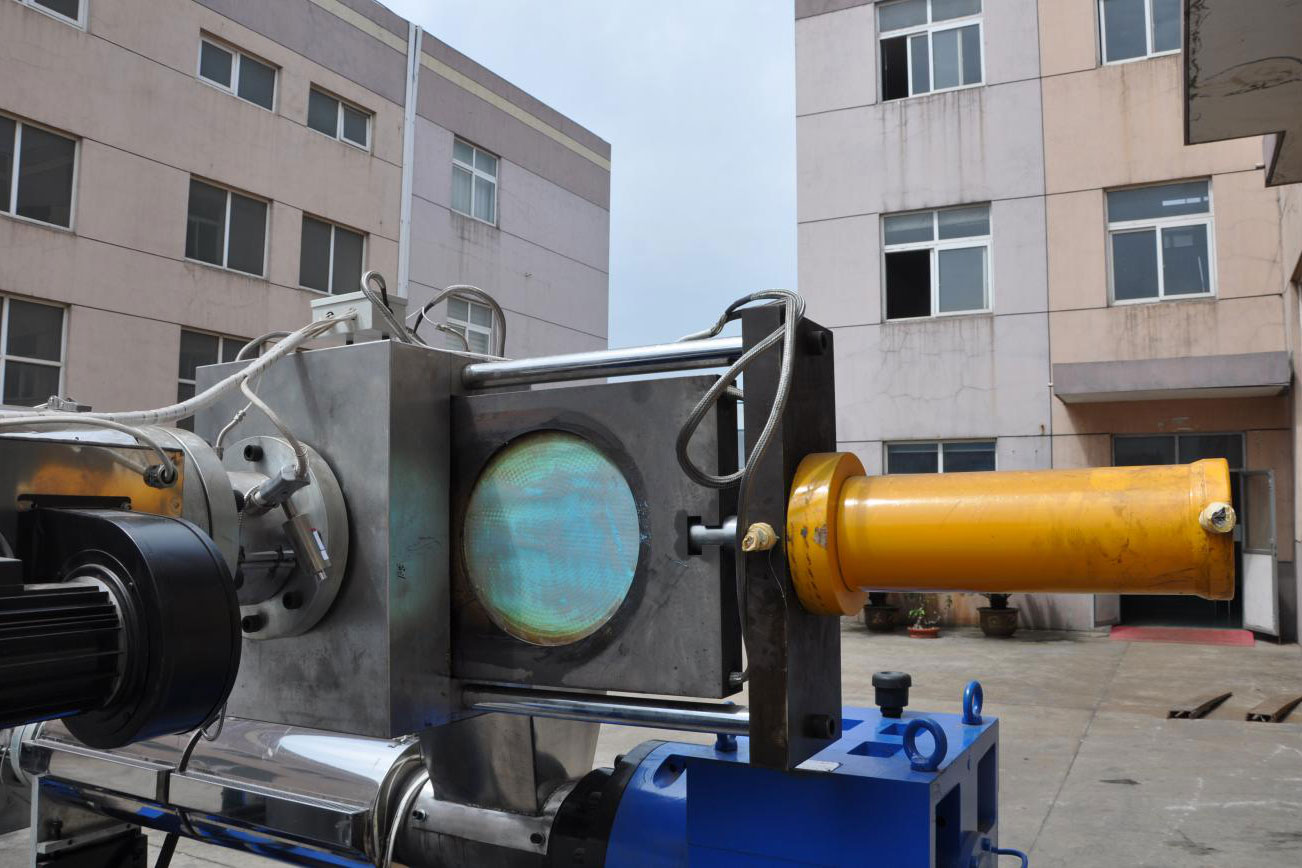

Parallel Twin Screw Extruder  (Hydraulic screen exchanger)

Double-plate type screen changer realizes non-stopping screen

Hydraulick screen exchange together with the hydraulic station usage,Used for filtration of the material mixture

(Hydraulic screen exchanger)

Double-plate type screen changer realizes non-stopping screen

Hydraulick screen exchange together with the hydraulic station usage,Used for filtration of the material mixture  (Hydraulic station)

Include the Energy Saver to increase the change net speed

(Hydraulic station)

Include the Energy Saver to increase the change net speed  Pelletizer

Pelletizer  (Vibrating Screen)

Three Layers, First Layer and Third Layer to filter out the unqualified granules, the second layer is for qualified granules.

(Vibrating Screen)

Three Layers, First Layer and Third Layer to filter out the unqualified granules, the second layer is for qualified granules. Description

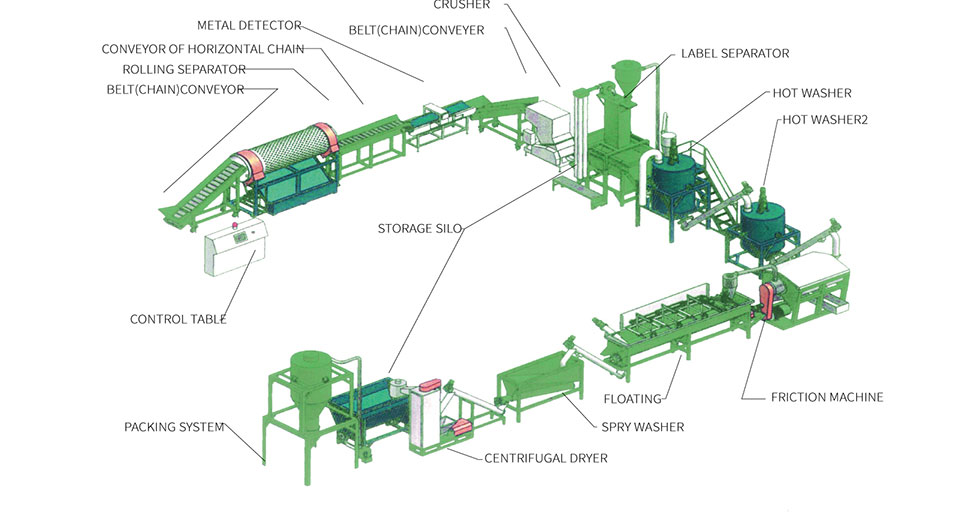

PET granulator this machine is suitable for PET (cola, mineral water bottle, etc.), automatic temperature control, avoid continuous heating, energy saving, reasonable design, simple operation, high production efficiency.PET granulator is mainly used for the regeneration granulation of PET flake materials after classification, crushing, cleaning, dehydration and drying, and the reduction of PET granulator into the form of materials for remanufacturing, especially as chemical fiber textile raw materials with a larger amount.

Materials

pet granulaters

Specification

| Model | TSSK65 | TSSK75 | TSSK92 |

| Stainless Steel Screw loader | 1.1kw | 1.5KW | 2.2KW |

| Screw Diameter(mm) | 63 | 72 | 92 |

| L/D | 32-32 | 32-64 | 62-64 |

| Capacity(kg/h) | 250-300 | 300-400 | 500-600 |

| Main motor power | 75kw | 90kw | 250kw |

| agglomerator power | 75kw | 90kw | 132kw |

| linelength | 14m | 16m | 18m |

| Hydraulic screen exchanger | 3kw | 2.2KW | 2.2KW |

| Hydraulic Station | 2.2KW | 2.2KW | |

| Watertank | 6000*500mm | 6000*800mm | 6000*800mm |

| Blowing drying system | 3kw | 2.2KW | 2.2KW |

| Pelletizer Machine | 3kw | 7.5KW | 7.5KW |

| Vibrating Screen | 1.5kw | 1.5KW | 1.5KW |

| Blowing machine | 3kw | 5.5KW | 5.5KW |

| Storage Hopper | 300kg | 300KG |