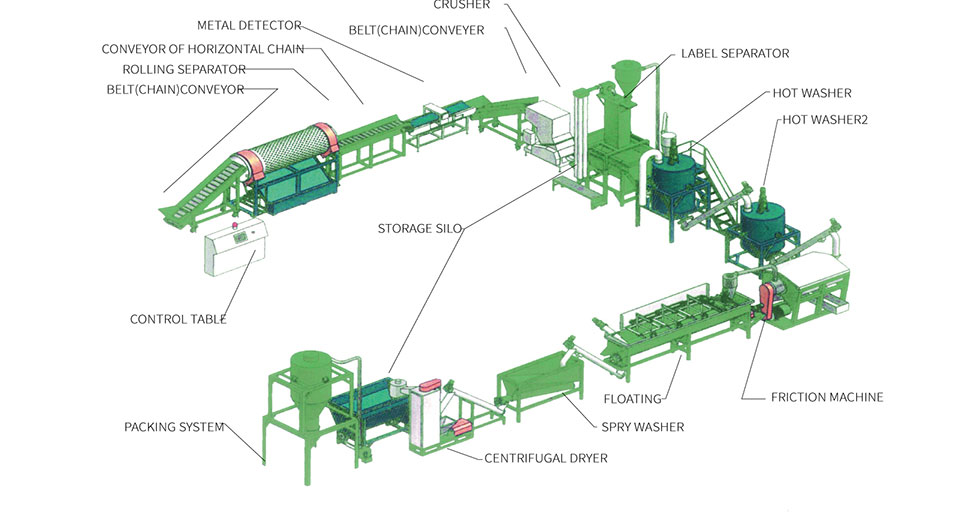

Plastic Granulating Machine

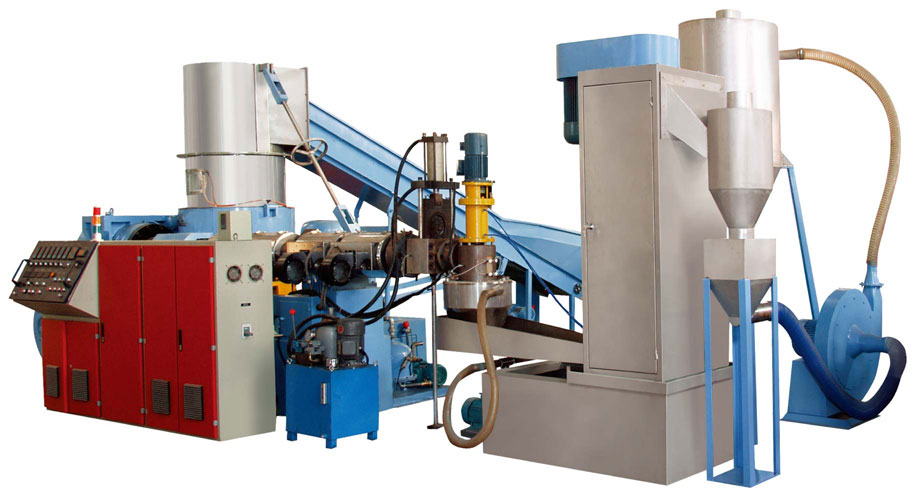

Plastic Film Single Stage Granulating Machine

Feed system

Material for screw loader :Stainless Steel

Feed system

Material for screw loader :Stainless Steel  Extruder

Process: Feeding, melting, conveying, extrusion, cooling, curing.

Extruder

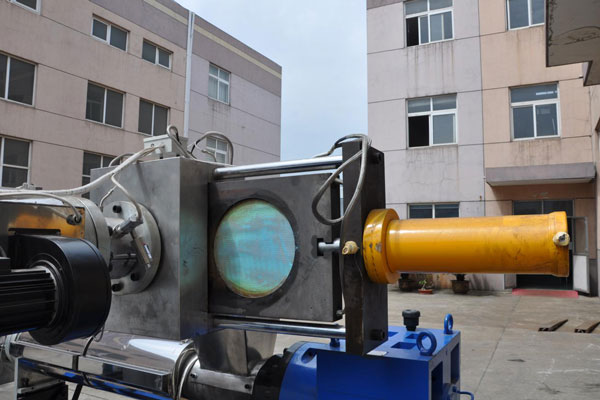

Process: Feeding, melting, conveying, extrusion, cooling, curing.  Hydraulic screen exchanger

Function: filter impurities The filter screen should be changed regularly

Hydraulic screen exchanger

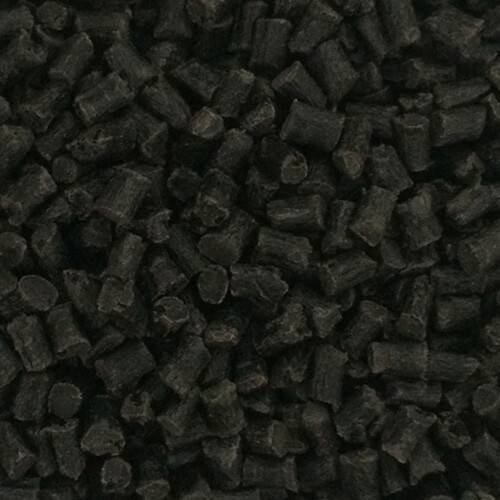

Function: filter impurities The filter screen should be changed regularly  When the molten polymer is extruded out of the die, it is cut into pellets by a granulator that rotates at a high speed

When the molten polymer is extruded out of the die, it is cut into pellets by a granulator that rotates at a high speed  1:using the principle of centrifugal drying and hot air drying, high drying efficiency;

2:the use of foot brake device, can quickly stop the rotary cylinder. 3:The dehydration basket is made of stainless steel.

1:using the principle of centrifugal drying and hot air drying, high drying efficiency;

2:the use of foot brake device, can quickly stop the rotary cylinder. 3:The dehydration basket is made of stainless steel.  Vibrating screen

Screening of qualified products

Vibrating screen

Screening of qualified products  Pipeline blowing drier

Pipeline blowing drier Description

Multifunctions of crushing and granulation. Whole plastic bags can undergo direct granulation without crushing

Double-column online screen exchanger with larger filtering area.

Water ring granule cutting avoid material staining.

Materials

Crushed PP woven bag

PP Woven Bag

PE Film

PE Agricultural Films

Specification

| Model | PE100 | PE120 | PE135 | PE150 |

| Belt Conveyor | ||||

| Main motor power(kw) | 1.5KW | 1.5KW | 1.5KW | 2.2KW |

| Main Extruder | ||||

| Screw diameter(mm) | 100 | 120 | 135 | 150 |

| L/D | 34:1 | 34:1 | 34:1 | 34:1 |

| Capacity(kg/h) | 200-250 | 300-350 | 350-400 | 400-500 |

| Main motor power(kw) | 90 | 110 | 132 | 160 |

| Line length(m) | 12 | 15 | 16 | 18 |

| Screen Exchanger | ||||

| Length(mm) | 240mm | 270mm | 300mm | 320mm |

| Hydraulic Station | ||||

| Main motor power(kw) | 2.2KW | 4KW | 4KW | 3KW |

| Hot-cutting System | ||||

| Main motor power(kw) | 1.5KW | 1.5KW | 1.5KW | 3KW |

| Centrifugal Drier | ||||

| Main motor power(kw) | 4KW | 7.5KW | 7.5KW | 7.5KW |

| Storage Hopper | ||||

| Main motor power(kw) | 1.5KW*2 | 3KW | 3KW | 3KW*2 |