Plastic Recycling & Washing machine

PP Bulk Bag Washing machine

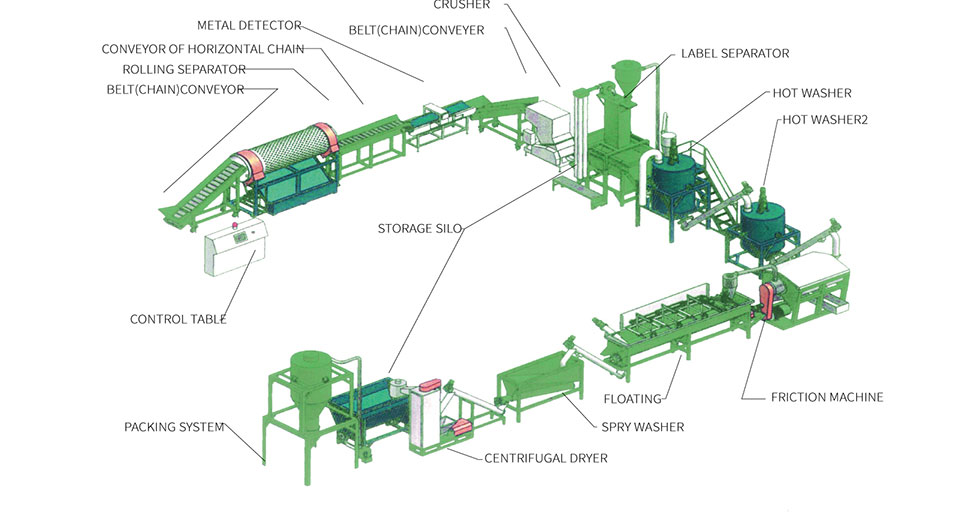

Conveyor separates impurities such as metals in the films and bags ,send the materials to the wet crusher machine .

Conveyor separates impurities such as metals in the films and bags ,send the materials to the wet crusher machine .  A wet crusher cuts the pp woven bags into small pieces approximately 10-20mm in size and moving onto the next piece of equipment .

A wet crusher cuts the pp woven bags into small pieces approximately 10-20mm in size and moving onto the next piece of equipment .  After crushing material from enters the mouth ,through the high speed on the axia of the blade flap and spray water to the common function of good cleaning effect.

After crushing material from enters the mouth ,through the high speed on the axia of the blade flap and spray water to the common function of good cleaning effect.  Using the hot air to take the humidity away from the clean material.

Using the hot air to take the humidity away from the clean material.  A storage hopper for the clean ,dry pieces of pp woven bags .

A storage hopper for the clean ,dry pieces of pp woven bags . Advantage

Suitable for different kind of plastic materials, are able to separate high density and dirty material.

With high speed washing machine, enable plastic materials inside the machine to be twisted, washed and separated dirt.

Whole set of electric facility are with automatic startup to protect wires in safe.

With Centrifugal Dryer that is optional, single screw rubbing drying machine can efficiently dry material, making the product 3% under moisture.

Materials

PP Woven Bag

PP Bulk Bag wash

Specification

| Capacity(kg/h) | 250-300 | 450-500 | 900-1000 | 1800-2000 |

| Beltconveyor | ||||

| MotorPower(kw) | 2.2KW | 2.2KW | 2.2KW | 2.2KW |

| Length | 4500mm | 5500mm | 5500mm | 5500mm |

| MetalDetector | ||||

| Size(mm) | 1200*800 | 1200*800 | 1200*800 | 1200*800 |

| Crusher | ||||

| MotorPower(kw) | 37kw | 90kw | 90kw | 110kw |

| ScrewFeeder | ||||

| MotorPower(kw) | 1.5KW | 2.2KW | 2.2KW | 2.2KW |

| High speed Friction washing machine | ||||

| MotorPower(kw) | 30KW | 37kw | 55kw | 55kw |

| washingtank | ||||

| Size(mm) | 6000*1000mm | 6000*1600mm | 6000*1800mm | 8000*1600mm |

| Screwfeeder | ||||

| MotorPower(kw) | 1.5KW | 2.2KW | 2.2KW | 2.2KW |

| FilmSqueezingmachine | ||||

| MotorPower(kw) | 75KW | 90kw | 185kw | 185kw |

| Pipeline | ||||

| Capacity(kg/h) | 250-300KG/H | 450-500KG/H | 900-1000KG/H | 1800-2000KG/H |

| StorageHopper | ||||

| Volume | 1m³ | 1m³ | 1m³ | 5m³ |